Sustainable Living

Another benefit that makes reusable drinkware attractive is the sheer number of resources it saves. Using a single paper cup per day for 10 years is equivalent to consuming 6 trees. Cutting down on waste and utilizing reusable products will help to reduce the waste created by the single-use industry.

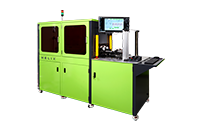

Smaller Footprint & Lower Maintenance Than DTG

DTG printers utilize a large amount of vital production floor space. On average, a DTG machine can take up around 67 ft2 (6.19 m²) of space. Adding drinkware to the mix will require another machine; however, the footprint is much smaller. The sleek design of the Helix® maximizes space by only utilizing 17 ft2 (1.57 m²) making it the perfect and compact addition to any company. On top of the spatial effectiveness of the Helix®, its maintenance is paramount to DTG machines. With DTG machines, the capping station require more maintenance, lint can clog print heads (which aren’t cheap to replace), and the white requires shaking. The Helix® eliminates all of these problems with both an automated capping station and an automated stirrer. More importantly, no lint means no problems and clean print heads!

Drinkware is a much simpler and higher margin product to manage compared to T-shirts. There is only “one size mouth”, so inventory is limited to just a few SKUs. Print-on-Demand works for a variety of great materials such as stainless steel, glass, coated metals, and plastics. All these materials enable brands and consumers to create beautiful, 360 degree gifts that people will value and use.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)