Benefits of Cylindrical Pad Printing

Cylindrical pad printing can provide for a number of benefits when it comes to printing your product.

- Produces clear images that do not become distorted

- Produces a durable image that can stand up to wear and tear, washing, and handling

- Print multiple parts quickly

- Can be used on any cylindrical item even if it has an unusual or difficult image surface such as mugs

How Does the Cylindrical Pad Printing Process work?

Cylindrical pad printing works by affixing the item into a designed parts fixture. These fixtures can be designed to hold one or multiple products. The product is then placed into the fixturing and moved into the machine. The printer will apply the ink to the pad that is in the pattern of the desired design. These designs will be broken up on each inking plate based on the color being applied.

Once the ink has been picked up onto the pad, the pad will move over and then press onto the item. If the item is getting multiple colors, it will move to the next station where the next pad will pick up the design for the second color and place it on the item. This process will continue until all colors are applied.

Automated Pad Printing for Large Orders

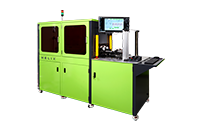

If you have a higher volume cylindrical pad printing project, you can consider having your project printed on automating equipment designed to process more products in a shorter period of time.

Using high volume automated pad printers can increase the output and reduce the cost allowing you to get a lower per piece price as the quantity goes up. You can choose from 4-station, 6-station, or 10-station dial tables to perform your automated process. The best part is, all you need to change to make any of these machines more automated for large orders is the fixturing.

4 and 6-Station Tables

These tables are ideal for use for single-color pad printing products. These tables can be equipped with an automated part loader, apart position verification station, camera visual inspection, and auto eject to make the process more efficient and allow you to produce higher volumes.

10-Station Dial Tables

These types of tables are ideal for those who are trying to automate multi-color pad printing projects. These tables can be equipped the same as the 4 and 6-station tables though they will lay on multiple colors during the process as the product moves through the machine. This type of automated process is commonly used in the manufacturing process of health and beauty products.

Benefits of Digital Cylindrical Printing

Digital cylindrical printing provides numerous benefits when marking your product:

- Produces photographic quality images

- Produces a durable image that can stand up to wear and tear, washing, and handling

- Allow you to print full-color images in one pass

- Can be used on any cylindrical item even if it has an unusual or difficult image surface

How Does the Digital Cylindrical Printing Process work?

Digital cylindrical printing works by inserting a part into a fixture. The fixture securely holds the part. The part then travels under a print head mechanism in which tiny droplets of CMYK (cyan, magenta, yellow, and black) colored ink are released in a particular pattern to form an image. Typically, one part is printed at a time and can take anywhere from 8-45 seconds to complete the job depending on artwork size and quality.

The ink used varies by the substrate for optimal adhesion, however, all inks are UV curable. After the UV ink is laid down on the part, the operator has the option to add a layer of varnish to give the print a nice shine and further protect it from abrasion.

Digital Cylinder Printing Automation for Large Orders

Conveyorized systems are in development in order to house more parts and expedite the printing process. Pick and place bots can also be used to load and unload parts and are available now.

What Cylinder Materials Are Ideal for Printing?

Some of the items that pad printing and digital printing can be used to print are perfectly cylindrical objects, but it can also be used to print items that simply have cylindrical features. Some of the products that can be used in the cylindrical printing process include:

- Cups

- Tumblers

- Thermoses

- Bottles

- Makeup Containers

- Machine Parts

- Carrier Tubes

- Pens

- Tubes

- Jars

What Industries Use Cylindrical Printing?

Almost any type of industry can benefit from the use of cylindrical printing. Some of the industries where this type of printing is most often utilized are:

- Health and Beauty

- Industrial and Manufacturing

- Marketing and Promotion

- Restaurant and Food Industry

- Sporting Goods

- Dinner and Glassware Manufacturers

No matter what type of cylindrical piece you are looking to add text, an image, or your logo to, cylindrical printing can provide you with a durable, vibrant image in moments. Contact Inkcups to learn how printing transforms cylindrical items into the beautiful and impactful printed pieces you desire.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)