- Equipment

- Inks & Supplies

- Services

- Applications

- Tagless

- Resources

- About Us

- Contact Us

There are two main competitors when it comes to plates for pad printing: laser etched and photopolymer. When comparing the two, laser plate making saves valuable time, typically 30 minutes. It is a more straight forward process leaving less room for human error. However, in the long run photopolymer plates will save you money as it is a less costly process when it comes to machine cost even with the added consumables.

The photopolymer plate process requires the following items: an exposure unit, plates, film positive, water (or plate developer, this is dependent on which plate type you chose), brush, dryer, oven, and some brain power. While the seems like a lengthy list, it is still the more cost-effective process compared to purchasing a laser plate maker.

Photopolymer plates require more attention than laser printed as the process is multi-stepped. Inkcups has a full step by step video tutorial made to watch, How to Make a Photopolymer Plate for Pad Printing Machines.

Photopolymer plates are a great option for a small business that continually prints a few different pieces of tag artwork repeatedly. Purchasing an exposure unit, the additional materials, and photopolymer parts grants many small businesses the flexibility to printer garment tags in-house, in turn saving money by being responsible for the labor themselves.

If your business is of a larger scale, in need of numerous different pieces of art, we advise you to invest in a laser plate-maker.

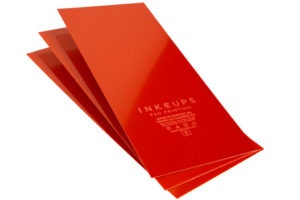

Inkcups offers six different types of photopolymer plates in two categories, alcohol wash and water wash. There is alcohol wash red, green, and gray plates. There are water wash dark green, orange, and light green plates. The primary difference between the two categories is the way in which the polymer plates are developed. Both have their advantages. Water wash plates, as the name implies do not require the use of chemicals, while alcohol wash plates are generally harder and allow better control over how deep the etch is.

When it comes down to which of these six plates is best for your application, it depends on three main factors:

From one photopolymer plate one can expect to get 10,000 to 25,000 impressions. With a premium material photopolymer plate, like the alcohol wash red, one can get up to 75,000 impressions.

From one photopolymer plate one can expect to get 10,000 to 25,000 impressions. With a premium material photopolymer plate, like the alcohol wash red, one can get up to 75,000 impressions.

Inkcups has previously compared the difference in thickness, exposure qualities, and expected impressions from each of the six plate types. Reference Photopolymer Plates to find out more.

The chosen artwork you wish to expose on the plate will determine other factors of the process. Depending on the nature of your artwork, it will affect the exposure time length, and choosing the correct line screen. Here you will find a comparison of exposure times between a small and large logo artwork.

Inkcups has a ton of information available about photopolymer plates, the process, and everything in between. The following documents and video will help you on your photopolymer plate journey.

Still have questions? Do not hesitate to give us a ring for additional information! 978-646-8980

Back to Blog Home

Add Your Comment