Did you know the world uses 500 billion plastic cups every year? Companies as big as Starbucks and Dunkin Donuts and as small as the local coffee shop rely on plastic cups to caffeinate the public. Downtown tea shops rely on plastic cups to concoct delightful varieties of tea, milk, ice, and tapioca pearls for a refreshing boba tea. Due to the global pandemic, many restaurants began offering to-go alcoholic beverages, in plastic cups. Many of these cups sport the logo of the company that created the hand-crafted drink. Those that don’t are missing out on a marketing opportunity. If your business is looking for a plastic cup printing machine, look no further. The Revolution® High-Speed Digital Cylinder Printer is the piece of machinery for the job.

How to Print on Plastic Cups

There are many solutions to the age-old question of, “how to print on plastic cups”. For starters, there are always the at-home DIY methods, but chances are, if you’ve found Inkcups and this blog post, you are looking for high output solutions. For that reason, one can print on plastic cups with a screen printer, pad printer, dye sublimation, DTF, and digital inkjet. For full-color, CMYKWW images, without extra waste, and a streamlined process, look no further than digitally decorating plastic cups.

Should I Print on Plastic Cups In-House?

Generally speaking, adding any aspect of your business to in-house rather than outsourcing creates flexibility, freedom, and often a price break. It is common knowledge that most industries suffered from supply shortages during the COVID-19 pandemic, and the shortages continue to this day. Specifically, the plastics supply chain has been disrupted since the beginning of the pandemic. So, what does this mean for businesses? The businesses that purchase plastic cups in bulk and print in-house were in a better starting position than those who solely rely on another company to supply them with their printed plastic cups.

Printing in-house also allows you better control over quality control. You have standards, but they might not align with your current printing partner. By cutting out the middleman you can print remove this disconnect between expectations. Many businesses that already have their own in-house cup printing machine note the added flexibility. They are able to print at their own speed, when their schedule allows.

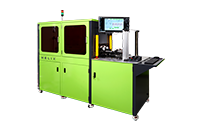

Let’s explore the possibility of adding a plastic cup printing machine, like the Revolution®, to your business.

Pre-Treatment for Plastic Cup Printing

There are two main types of pre-treatment; corona and plasma. Both pre-treatment methods have the same end goal- to alter the surface tension of the substrate to make the surface a more welcoming location for ink to adhere to.

- The plasma pre-treatment uses the plasma portion of the flame.

- The corona pre-treatment does this with an electrical type of charge that is applied to the surface of the vessel. Often this pre-treatment is strong enough to eliminate the need for any other accompanying treatment method.

Depending on your cup printer needs, the Revolution® can be equipped with either an integrated corona or plasma treatment system. To find out which your plastic requires, go ahead and send in your vessel for adhesion testing.

What is the Best Ink for Plastic Cups?

Pair your plastic cup printing machine with S1 UV Inkjet Ink for optimal adhesion. While we’ve already put S1 ink to the test for plastic in general, we have found that not all plastics are the same. Inkcups offers a complimentary service and strongly suggests sending in the plastic cups you intend to print on so we can test it in-house to guarantee the best results possible.

Pair your plastic cup printing machine with S1 UV Inkjet Ink for optimal adhesion. While we’ve already put S1 ink to the test for plastic in general, we have found that not all plastics are the same. Inkcups offers a complimentary service and strongly suggests sending in the plastic cups you intend to print on so we can test it in-house to guarantee the best results possible.

S1 UV Inkjet Ink is a well-rounded ink that strongly bonds to plastic, stainless steel, ceramic, and more. The line is composed of Cyan, Magenta, Yellow, Black, White, and Varnish to create vibrant, full-color graphics. The most recent addition to the line, Vivid White, is the whitest ink available on the UV inkjet ink market. This ink is perfect for printing on dark colored backgrounds. Read the official press release here, Inkcups Vivid White Digital Ink Now Lives Longer and Offers 50% More Opacity.

Key Features of the Revolution® Plastic Cup Printing Machine

Of all the impressive cylindrical printer line Inkcups offers let’s take an in-depth view of the Revolution®. It was first introduced to our product line in 2019 and has quickly taken off. The Revolution® can print high-quality, full-color graphics at an impressive 600 parts per hour output.

Of all the impressive cylindrical printer line Inkcups offers let’s take an in-depth view of the Revolution®. It was first introduced to our product line in 2019 and has quickly taken off. The Revolution® can print high-quality, full-color graphics at an impressive 600 parts per hour output.

- 360-Degree Helical Printing

- Designed for cylindrical printing applications

- Prints longer, continuous images (up to 220mm) in a single motion

- Eliminates visible seam lines caused by multiple passes in single-pass printing

- High-Efficiency Production

- Equipped with 12 stations for streamlined operation

- Includes automatic load and unload features

- Integrated pre-treatment system enhances print adhesion

- Advanced Print Head Configuration

- Separate dedicated print heads for white and varnish

- CMYK printed in a single station for optimal dot placement

- Delivers high-resolution output and exceptional color consistency

Is a Revolution® right for your business? Get started today by contacting one of our knowledgeable sales representatives for more information.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)

Pair your plastic cup printing machine with S1 UV Inkjet Ink for optimal adhesion. While we’ve already put S1 ink to the test for plastic in general, we have found that not all plastics are the same. Inkcups offers a complimentary service and strongly suggests sending in the plastic cups you intend to print on so we can test it in-house to guarantee the best results possible.

Pair your plastic cup printing machine with S1 UV Inkjet Ink for optimal adhesion. While we’ve already put S1 ink to the test for plastic in general, we have found that not all plastics are the same. Inkcups offers a complimentary service and strongly suggests sending in the plastic cups you intend to print on so we can test it in-house to guarantee the best results possible. Of all the impressive

Of all the impressive

Add Your Comment