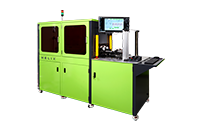

The Helix®+ joins the Helix® line of cylindrical inkjet printers as the steppingstone between the Helix® and Double Helix®. Unique in design as the Helix®+ begins as a single tunnel machine with the ability to later upgrade to a double tunnel machine. This flexibility is a huge benefit for any company looking for a drinkware printing machine to grow alongside their operations.

The Helix®+ sports the updated appearance that all Helix® line of cylindrical printers now have. For easier access and maintenance of the machine a wider frame and illuminated interior are now standard.

Print superior quality full-color (CMYKWW + varnish) images on straight-walled and tapered cylinders up to 8.6”. With recent upgrade, ColorBoost, forgo the quality versus pass count trade off and achieve 12 pass quality and 6 pass speed or 8 pass quality at 4 pass speed. To achieve this superior image quality, ColorBoost allocates 2 channels per head, with a dedicated head per color rather than 1 channel per head in competitive machines.

Other standard features available on the Helix®+ besides ColorBoost include automatic cylinder height adjust, automatic intelligent diameter measurement, the Helix® software package, and safety feature no part, not print. Additional options that can be added the Helix®+ include jettable primer, and the ability to add integrated corona or plasma pre-treatment.

Print innovation known and loved by Helix® and Double Helix® users will be available on the Helix®+. Differentiate from competitors further with print techniques such as mirror print, Lustre Effect, tone-on-tone, full coverage, contour print and more.

For more information, learn more about the Helix®+ from Inkcups CEO, Ben Adner below:

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)

Add Your Comment