As the second most popular promotional item, drinkware has infiltrated our lives in so many aspects. From small social gatherings like birthday parties to sporting events there is an opportunity to present branded drinkware. At the birthday party the brand is the person being celebrated, at the sporting event it enables multiple opportunities; the team itself and the sponsor. Despite whether the gathering is your local venue or local schools stadium the quality of the drinkware matters.

When it comes to quality, what comes to mind? You might not even notice, but generally we are sizing up every item placed in front of us. Drinkware is no different. Typically, we begin by looking at overall image quality- no one is impressed with blurry graphics! Next, color. Are the colors true to the brand? Finally, is there anything that sticks out about the drinkware, in 2023 standards are high! A seam in a print may not seem like a big deal, but it affects the overall perception of the quality.

Print Quality: Achieving Seamless Printing

When it comes to quality, the well-trained eye will look for full-color, high resolution, seamless graphics on drinkware. Print quality can be attributed to the method of printing. For this blog’s purpose we will explore single pass, multi pass, and helical printing.

Single Pass Printing

In single pass printing, the resolution of the image is limited by the resolution of the print head. Images that are larger than the print head will require stitching, which leaves a visible line in the print. Any visible line on a print drastically decreases print quality. That being said, single pass printing is the fastest of the three options and brands may find themselves pinched for time and opting to sacrifice quality for time management.

Multi Pass Printing

Multi pass printing, like single pass printing is also limited to the resolution of the print heads. Multi pass printing resembles that of your home printer, the printhead(s) move left to right, overlapping ink as it travels. This is both a time consuming and cumbersome process, resulting in the poorest quality of images between it, single, and helical.

Helical Printing

Helical printing utilizes a limited number of print heads, but still allows continuous imaging in a helical pattern. Print technicians can prioritize print resolution, speed, and curing or higher speeds, making it the most flexible of the three methods. Compared to single pass printing, helical printing can achieve much higher resolution images and is much more efficient. Additionally, helical printing stands out for its interlacing of inkjet drops which smooths out band lines resulting in uniform coverage.

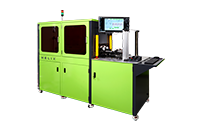

Helix ONE® for Seamless Printing

With industrial cylindrical inkjet printers, print high-quality, full-color seamless graphics. Due to helical printing, the Helix® line of cylindrical inkjet printers achieve stunning graphics with superior resolution, free of any stitching and unseemly seams on the vessel’s walls.

With industrial cylindrical inkjet printers, print high-quality, full-color seamless graphics. Due to helical printing, the Helix® line of cylindrical inkjet printers achieve stunning graphics with superior resolution, free of any stitching and unseemly seams on the vessel’s walls.

Much like the first additions to the Helix® line, the Helix®, Helix®+ and the Double Helix®, the Helix ONE® utilizes helical printing to reproduce full-color vibrant graphics on a wide variety of substrates. Printing full-color and seamless elevates a piece, creating higher value and a higher return. Often, drinkware with a white line running down its wall can feel cheap and lower quality.

The Helix ONE® with LV series UV ink can decorate a variety of substrates including plastic, acrylic, stainless steel, and powder coated. Benchtop in design, the Helix ONE® knows no bounds when it comes to print quality. With a max resolution of 600 x 1200 dpi, ability to print on parts from 2” to 13” and the diameter of 1.77” to 4.7” the Helix ONE® is a great cylindrical printer for those that are brand new to drinkware printing to seasoned printers.

To see the Helix ONE® printing, please view the video below:

Contact Us

To find out more and connect with the sales representative closest to you, visit: Contact Us. Additional resources you may find of use include: What is Rotary Printing.

For further information on our entire line of drinkware printers, please visit: Cylindrical Inkjet Printers.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)

Add Your Comment