With the NFL season right around the corner, it’s crucial to address a key element of attending a live game: your clear tote bag. It’s the only acceptable option for entry, providing football fans with a convenient space to store essentials like wallets, phones, and mints. Stadium approved clear bags are an additional revenue stream that print shops need not sleep on. With football stadiums requiring guests to abide by certain rules for entry, this opens a new product for apparel decorators and print shops alike to decorate. However, the material used for clear stadium bags is incredibly tricky to decorate as it is highly heat sensitive. Therefore, print shops might shy away from offering them. With technological advances in digital UV printers, including the specialization of flatbed printers, it’s now easier to decorate even the trickiest of fabrics.

What are Stadium Approved Clear Tote Bags?

The bags we’re discussing today can be made from clear plastic, vinyl, or PVC (Polyvinyl chloride). In 2013, the NFL announced a bag policy requiring fans to only bring in clear plastic, vinyl, or PVC bags, allowing for smoother security checks and quicker entry into stadiums.

What Size Stadium Bags are Approved?

According to NFL specifications, bags must be clear plastic, vinyl, or PVC, not exceeding dimensions of 12” x 6” x 12”. Additionally, bags should lack buckles, grommets, hardware, or any other decorative elements. The guidelines further outline branding restrictions, permitting logos to be printed on one side of the bag, with acceptable logo dimensions appearing to be approximately 5” x 5”, as indicated in the renderings provided.

Visit : NFL Clear Bag Policy

Clear Tote Bag Characteristics

Stadium approved clear bags can come in a wide variety of shapes and sizes, including tote bags, crossbody bags, wristlets, drawstring totes, clutches, and more.

Events for Clear Tote Bags

While the list is ever-growing, the most popular occasions for grabbing a stadium approved clear bag include football games, basketball games, hockey games, arena events, festivals, and concerts. It should be noted that while these clear stadium bags are typically used for regulated events, that isn’t always the case. There are many clear PVC bags on the market that far exceed the size allowance of those permitted into the NFL, therefore there must be an additional need outside. For instance, there are many open top tote bags available that far exceed 12” lengths.

Methods for Decorating Stadium Approved Clear Tote Bags

Clear PVC bags are a tricky substrate to decorate. Traditional methods such as screen printing, heat transfer, and DTF are incredibly limited when it comes to decorating these heat-sensitive materials. Therefore, enter digital UV printing machines for efficient decoration of these bags. It should be noted that there has been some success with heat transfers; however, heat transfers are applied at a low temperature to avoid distortion after the vinyl has been applied. It is also recommended in this practice that users utilize a Teflon heat pillow.

Digital Decoration on Clear PVC Bags

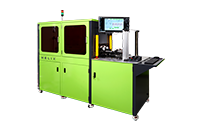

The XJET Switch is a state-of-the-art printing technology optimized for digitally decorating a wide range of tote bags, including those that are heat-sensitive, like stadium approved clear bags. The XJET Switch utilizes UV flatbed technology in a specialized configuration with platens for tote bags and UV LED light to instantly cure, eliminating the need for heat presses or any additional heat-to-cure steps.

The XJET Switch is a state-of-the-art printing technology optimized for digitally decorating a wide range of tote bags, including those that are heat-sensitive, like stadium approved clear bags. The XJET Switch utilizes UV flatbed technology in a specialized configuration with platens for tote bags and UV LED light to instantly cure, eliminating the need for heat presses or any additional heat-to-cure steps.

This specialized flatbed UV printer is designed for full-color direct-to-reusable bag applications, hard goods, and more. Harnessing the power of UV-curable inks and advanced digital printing technology, this cutting-edge machine enables seamless production of vibrant, high-quality prints directly onto flat surfaces, including bags.

The XJET Switch boasts a total print area of 13.8 inches x 25.6 inches (350 mm x 650 mm) with a maximum part height of 8 inches (203.2 mm). Distinguished by its patented continuous printing technology, this state-of-the-art device allows operators to load products while the machine is in operation, optimizing production efficiencies.

This flatbed UV printer enables the addition of multiple plates within the maximum width. It also facilitates a seamless switch from 180 degrees to 90 degrees for in-process pre-treatment. Moreover, the intuitive tooling design ensures effortless loading and unloading, while an optional smart spring-loaded tooling system further enhances convenience.

Unlike traditional printing methods such as screen printing or heat transfer, UV printing on tote bags offers the advantage of full-color (CMYKWW) graphics and images that are ready for stacking and shipping immediately after printing. The XJET Switch’s revolutionary UV printing eliminates the need for additional curing steps, saving valuable time and resources.

Additionally, this advanced flatbed UV printer significantly reduces waste compared to alternative methods, enabling customers to embrace a sustainable and eco-friendly printing process. The XJET Switch swiftly and expertly decorates clear PVC tote bags, otherwise referred to as stadium approved clear bags, which many major venues in the United States mandate as the only bags permitted within the premise. The NFL has strict guidelines that must be observed to enter the arena and has set the precedent for other mass gatherings as well.

In conclusion, digital printing allows print shops to create custom, eye-catching designs on stadium-approved clear bags, a product in high demand due to venue regulations. This widens their profit potential by catering to a new market and eliminating limitations from traditional printing methods on heat-sensitive materials. Digital printing also reduces waste and allows for smaller print runs, which can be more profitable for shops.

To get started, or to gather additional information on the XJET Switch, please contact us today.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)

The

The

Add Your Comment