Pad Printing of the Past

While the primitive pad printing techniques of the 1800’s far from resemble the pad printing machines available in 2022, the primary function remains the same. Pad printers are made up of the same three primary components: the pad, the plate, and the ink. (Technological advances and innovation over the years has brought around motors, servos, and ink cups.) The first pad printers transferred images by hand to products by using a bag of soft gelatin, which over time has been replaced with silicone pads. Initial printing plates were copper sheets engraved by hand, while today’s users have three options: they can outsource the plate making process, use an exposure unit, or use a laser plate maker. Over 200 years since inception, times have changed, but pad printing has remained popular due to its incredibly versatile nature to directly decorate countless substrates.

The process of transferring a 2D image to a 3D object works for a plethora of industries including pharmaceutical and medical devices, textile/ apparel, automotive, consumer goods, electronics, and so on. Promotional products such as pens, stress balls, frisbees, travel mugs and travel sized hand sanitizer bottles are ideal for pad printing one- or two-color logos for branding. The first pad printing machines of the 1960s were used to print on watch faces- look how far pad printing opportunities has branched out.

Pad Printing of the Present

Today, the entire process of pad printing happens rather quickly, the ink cup loaded with ink is magnetically attached to an etched plate, (otherwise referred to as a cliché) where the ink cup runs back and forth across the plate depositing ink in the recess and removing excess ink elsewhere. Next the pad picks up the ink from the etched surface and then presses the image onto the object. Most notably pad printing is known for its unparalleled ability to print on irregularly shaped surfaces.

Over the years pad printing has held steady due to its low startup costs, flexibility, and versatility. For instance, the same pad printer can be used for printing on 3D objects as well as for tagless apparel applications.

Pad Printing Ink

Pad printing inks come in a variety of different make-ups to ensure the best adhesion to the chosen substrate. For example, Inkcups offers a specialized silicone pad printing ink. Other specialized inks include ones specially formulated for ceramic or glass, wood, coated metals, and the list goes on. During the ink mixing process, ink is mixed with a solvent and hardener. Solvent evaporates once it is exposed to air resulting in a tacky quality to the ink for ease of transfer from pad to substrate.

Pad Printing Plates

An important aspect of pad printing is the plate. Pad printing plates are needed to hold the ink of the image that has been etched into the surface. Plate making can be achieved with a laser plate maker, exposure unit or can be outsourced. There are extensive options of plate materials available including: Cobalt® Steelback, Cobalt Ultra, Laser Red, Laser Orange, DuraLaze, Onyx, thick Steel, alcohol wash red, and water wash orange, to name a few.

Methods of Making Pad Printing Plates

There are two methods of creating a printing plate, with one using a UV exposure unit, and the second known as “computer to plate” using a laser engraver.

UV Exposure Process of Plate Making

The traditional technique of etching a photopolymer plate with an exposure unit is a time-consuming process, typically taking 30 minutes from start to finish. While this process is the most cost-effective method it requires a lot of practice and attention. For instance, there is a learning curve when it come to different exposure times dependent on image size. Of this process, the hardest part is making a good film positive. The next hardest thing is getting consistent results based on numerous variables.

Polymer plates are made up of a photosensitive material which alters its chemical composition when exposed to ultraviolet (UV) light. The use of a film positive blocks off areas of an image from being exposed to ultraviolet light, etching the other areas of the plate. Often a second exposure with a screen is necessary, which regulates the depth of the etch. Next, the plate is then soaked in alcohol or water then dried and re-exposed to harden fully.

Polymer plates are an economical option for businesses in need of constant artwork changeover. If properly stored, exposed polymer plates will have a shelf life of approximately one-year.

Computer to Plate: Laser Plate Making Process

The plate making process with the use of a computer and laser plate maker goes as follows: to begin, artwork is prepped in a graphics program such as Adobe Illustrator. The artwork is then sent over to the laser plate maker, the plate is loaded, and the plate is etched in 5-7 minutes (the time varies for specific laser plate makers.) From there unload your plate and walk over to your pad printer.

Benefits of a Laser Plate Maker

Elevate your printing process by adding a laser plate maker to your production floor. Etching your own plates brings the process in-house, allowing the ability to change your design on a whim, increasing efficiency, and creating flexibility when it comes to demand and deadlines. Furthermore, the use of a laser plate maker offers unparalleled detail and repeatability.

Ease of Use

Of the laser plate making process, the etching of the plate is straight forward. It is the artwork preparation process that requires a level of attention and skill. Additionally, Inkcups offers remote training for newly acquired laser plate makers to ensure the highest level of satisfaction with your new machine.

High Quality Results

The image quality is highly dependent on the plate etch. Ensure complete satisfaction by mastering the art of plate etching for yourself.

Lower Costs

Eliminate consumables and bring the laser plate making process in-house to save money in the long run. Initial startup costs include: the laser plate making machine, a computer, plates, and a ventilation station. However, once these have been purchased, except for laser plates themselves, you are set for years to come.

Benefits of Laser Plate Makers In-House

Depending on the scale of your business adding a laser plate maker to your operations can be vastly beneficial for the entire printing process. A laser plate maker on the production floor offers added flexibility and full control of the process. Ensure that plates are up to your standards and done when you need them. Out-sourcing plates can result in shipping delays increasing the entire turn around.

Inkcups Laser Plate Etching Service

As one size does not fit all, adding a laser plate maker to every production floor is a reach. At Inkcups, we offer a service to etch plates for any customer in need of the service.

Inkcups’ in-house plate etching service is easy. Simply send in your artwork and an etched plate will be mailed back to you.

For customers within the United States (and a few international locations), plates can be at your door as quickly as 1-2 business days. Take the guess work out of plate making and pass the responsibility off to an expert. To ensure accuracy and quality nothing gets etched or shipped prior to proof approval.

Laser Plate Maker Options Available

Inkcups currently has two different laser plate makers available, the Cobalt ONE Cobalt PRO. The three options vary in numerous ways, allowing for businesses to find the best fit for their operations. Deciding factors toward which laser plate maker go far beyond pad printing output however.

Cobalt PRO

The Cobalt PRO joins the Cobalt ONE in the Inkcups laser plate making offerings. The Cobalt PRO stands out from the rest of the Cobalt line as it has a much larger etching area with the ability to etch a large plate or multiple plates at once. Not only that, but the Cobalt Pro can etch the widest variety of plates ranging from Duralaze to exposed polymer. Additionally, the Cobalt PRO compared to the Cobalt ONE, is the highest wattage laser Inkcups has available. While it’s primary function is a CO2 laser plate maker, the Cobalt PRO can be used to cut fabric or acrylic, and to engrave various materials such as plastic and wood.

The Cobalt Pro is equipped with a servo-driven motor and when paired with a computer can produce high-resolution pad printing plates without the use of film positives, chemicals, or concern for depth control. As previously mentioned, the Cobalt Pro has a whooping 40W ceramic core laser, allowing it to function as a laser maker, cutter, and engraver. The Cobalt Pro produces high resolution graphics (up to 1500 dpi) by employing CO2 laser technology.

The Cobalt PRO makes for an invaluable addition to any production floor, but especially those in the promotional products market.

Q&A Session to Expand on Benefits of a Laser Plate Maker

To further expand upon the benefits of adding a laser plate making to your business we interviewed Ian Bedford. Ian, Inkcups’ Senior Project Engineer gave the following responses:

Q. At what level of demand should a business consider bringing the plate making process in-house?

A great way for a business to approach if it is cost effective to add a laser plate maker to their operations is to begin by comparing current expenses to the total cost of a laser plate maker. Over the course of a month track the following: how often artwork is changed, how many plates are used, how much time is spent waiting outsourcing or at an exposure unit. Those three factors can determine whether it’s time to invest in a laser system.

Q. Next, how does a business select which laser plate maker is best for their operations?

When throughput is essential, they should go for the Cobalt One or Cobalt Pro. The Cobalt Pro is faster on bold images and multi-plate capable.

Q. What is the difference between a tagless etch versus a promotional etch?

A tagless etch is deeper at 40-60µm* versus a promotional which is at 20-25µm. Customers looking to etch plates for tagless applications would be best suited with the Cobalt One. The Cobalt Pro would be best for promotional products industry.

*µm is the abbreviation for a micrometer, which is one millionth of a meter. Micrometers are used as etches are typically so fine.

To discuss if the benefits of adding a laser plate maker to your production floor contact us today.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

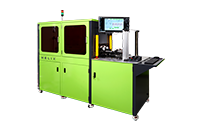

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies (tagless.inkcups.com)

Tagless Supplies (tagless.inkcups.com)

Add Your Comment