Inkcups Helix® Range Helps Bottled Goose Take Flight

Proper Goose, a personalised gift producer based in Surrey, started out in 2015 designing and making Limited Edition First Day Covers, specially designed envelopes desirable to collectors. Before long, they identified a wider range of applications for the printing equipment they were using and diversified into the burgeoning personalised gift market.

The business name FDCovers was no longer fit for purpose, and in 2016 Proper Goose was born. From there, the production of personalised gifts for all occasions became the leading product focus, from pet treat tins adorned with images of furry friends to crystal champagne flutes ornately decorated with wedding dates, and even decks of cards featuring familiar faces, the Proper Goose gift range is extensive.

Although the product line is diverse, the glass products proved to be the most popular with customers. “Proper Goose is a retail-focused personalisation company,” explains director Luke Gosling. “We print in-house doing all fulfilments directly to our customer. The majority of this is on glassware, so champagne flutes, bottles, and candles.”

To meet demand for personalised glassware products, Proper Goose invested in the Helix® Hi-Fi, Double Helix®, and Magicoat® Pre-Treatment System from Inkcups in 2021. Before long, the speed and quality of the work produced on the Helix® models brought about a brainwave for the Proper Goose team. “We were looking for a gap in the market, and drinkware was one,” continues Luke. “We kept wondering why there were no drinks printed with personalisation.”

“We bought an Inkcups Helix® machine, and then when we actually started seeing the capabilities of the machine, the combination between the quality of the print and the speed, that’s when we realised that we could take personalisation on drinkware to the market. So, we decided to open up a second part of the company, Bottled Goose, which is trade focused.”

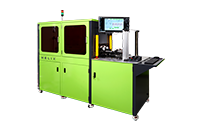

The Helix® range of industrial cylindrical inkjet printers convert digital images and print directly onto cylindrical, straight-walled, or tapered substrates. Products in the Helix® range include the new Helix ONE® benchtop cylindrical printer, the flagship Helix® cylindrical inkjet printer, recently rebranded to the faster Helix® 2.0, the Double Helix® with two print stations, and the modular Helix®+ UV cylinder printer, a ‘stepping stone’ model between the Helix® 2.0 and Double Helix® that allows users to begin with a single tunnel and upgrade to a double tunnel machine.

“We have three Inkcups Helix® machines; the Hi-Fi Helix®, the single Helix®, and the Double Helix®,” explains Tamas Gal, Head of Production at Bottled Goose. “With the Inkcups Helix® range, we can print onto many cylindrical and tapered products, and we can even print on prefilled glass bottles thanks to the transparent curing system. We also have a high-capacity Magicoat® Pre-Treatment System. We can print volumes as low as one for personalised gifts, up to tens of thousands for major brands.”

Inkcups technology didn’t just allow Proper Goose to launch a whole new business model; it also facilitated further software investment that allows Bottled Goose clients to take personalisation to the next level. “The unique capabilities of Inkcups printers allows extremely precise colour matching and positioning,” explains Peter MacKinnon, Digital Lead at Bottled Goose. “When we realised the true capabilities of the Inkcups printers, we had a lightbulb moment that we could push our software a little bit further and allow our clients to offer greater personalisation solutions for their customers.”

Partner in Wine, a producer of customised insulated wine bottles and tumblers, is a notable example of Inkcups solutions paving the way for a broader relationship between Bottled Goose and its clients. “We’ve been doing a lot of [Partner in Wine’s] personalisation for them,” explains Cherie Noy, Operations Manager at Bottled Goose. “The customer will go onto the website, pick the bottle they want, the colour they want, decide what personalisation – initials or name, whether they want that horizontal or vertical. That artwork immediately comes to our Inkcups printers, and we will then print that. So, it’s really, really quick, and really, really simple.”

Understandably, Partner in Wine and other brands don’t have room for compromise when it comes to standards. For Bottled Goose, the new trade focus means an additional layer of scrutiny, as Luke explains: “Trust is one of the most important things in trade printing. These brands are very protective about the colour and quality of the print displayed on product. That’s why we’re using Inkcups machines.” Cherie adds: “The great thing with Inkcups is the technology and quality of the print that can be achieved. And that elevates products, giving them that icing on the cake that just takes them that stage further. Inkcups printers will elevate people’s brands to the next level.”

Looking to the future, the Bottled Goose team are planning on building on the trade arm’s success and continue to expand, supported of course by the existing Inkcups printers, with more likely to follow. Cherie continues: “We need to be flexible, adaptable, and work closely with Inkcups, and that relationship has been brilliant. I think that’s what’s going to help us come to be the leading UK cylindrical printer, using Inkcups machines.”

Luke echoes this sentiment, concluding: “Our plans are to scale up the business, be in more stores and allow more people to sell our product range. Using Inkcups machines is very scalable as well, it allows us to have very high capacity, so I have no doubt that they will be a great partner for us as we expand Bottle Goose.”

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies

Tagless Supplies