What is a Pad Printing Plate?

A pad printing plate, also known as a cliche, holds the image to be printed. The plate is etched with the image. There are two type of plate etching process: photopolymer and laser.

Photopolymer Plate-making

Photopolymer plate-making requires the use of photosensitive plate material and a UV exposure unit. The plate is exposed to UV light numerous times, each with a different component such as a film-positive or line screen film. Exposing pad printing plates is the more cost-effective solution to plate-making, however, the photosensitive curing process is significantly longer than laser plate-making, taking upwards of 30 minutes to etch a plate.

How to Make Photopolymer Plates for Pad Printing Machines

Computer-to-plate Laser Plate-making

Laser plate-making is the process of etching a plate with a Co2 or fiber laser. Computer to plate technology allows for complete repeatability without concern for variation in etch depth, dot pattern, and image quality. Laser plate-making is extremely fast, typically etching a plate in 5-7 minutes.

Additional Resources:

Can I Etch Laser Plates with My C02 Laser?

Image Sizing Template for Pad Printing Ink Cup

Learn more about our pad printing plates

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

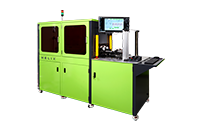

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies

Tagless Supplies