Silicone Ink SI Series

SI Series pad printing ink is a 2-component silicone ink solely designed to print on silicone rubber parts. Applied via either screen or pad printing, SI Series silicone ink is opaque, glossy, flexible and exceptionally resistant to abrasion. Ideal for wristbands, phone cases, oven mitts and various silicone items where other solvent-based inks can pose a challenge. Silicone products are everywhere! Read about the top 5 ink applications for printing on silicone with silicone ink.

The only thing that adheres to silicone is silicone, therefore our SI Series Ink is primarily made up of silicone. Silicone ink is the only type of print that can bend, stretch, and move with silicone as well as withstand high temperatures that silicone is known to frequently be used for. Once fully cured, silicone ink will hold up to anything silicone can. If your silicone melts during the curing process, chances are, your product is not 100% silicone. Learn more about silicone printing: how to test if your product is actually silicone.

SI Series silicone ink can be either pad printed or screen printed. While we recommend pad printing, due to the ease, screen printing can certainly be an option. Pad printing lays down less ink to achieve the same look, therefore ink costs are down and curing time is shortened. Find out more in our blog post about Silicone printing: Pad printing vs Screen Printing.

SI Series silicone pad printing ink is available in 15 standard and 2 metallic shades. Custom color-matching is available.

The idiosyncrasies of printing silicone products outline the ins and outs of silicone ink.

- Extremely flexible

- Slow drying

Listen to a recent podcast with our Ink Manager, Joe Shairs, on silicone ink: The Dos and Don’ts of Printing on Silicone.

Tagless Printers

Tagless Printers Cylindrical Inkjet Printers

Cylindrical Inkjet Printers UV Flatbed Printers

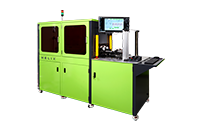

UV Flatbed Printers Pad Printing Machines

Pad Printing Machines Pretreatment Systems

Pretreatment Systems Inkjet Printing Auxiliary

Inkjet Printing Auxiliary Laser Plate-Makers

Laser Plate-Makers Inkjet Printing Supplies

Inkjet Printing Supplies Pad Printing Supplies

Pad Printing Supplies Tagless Supplies

Tagless Supplies